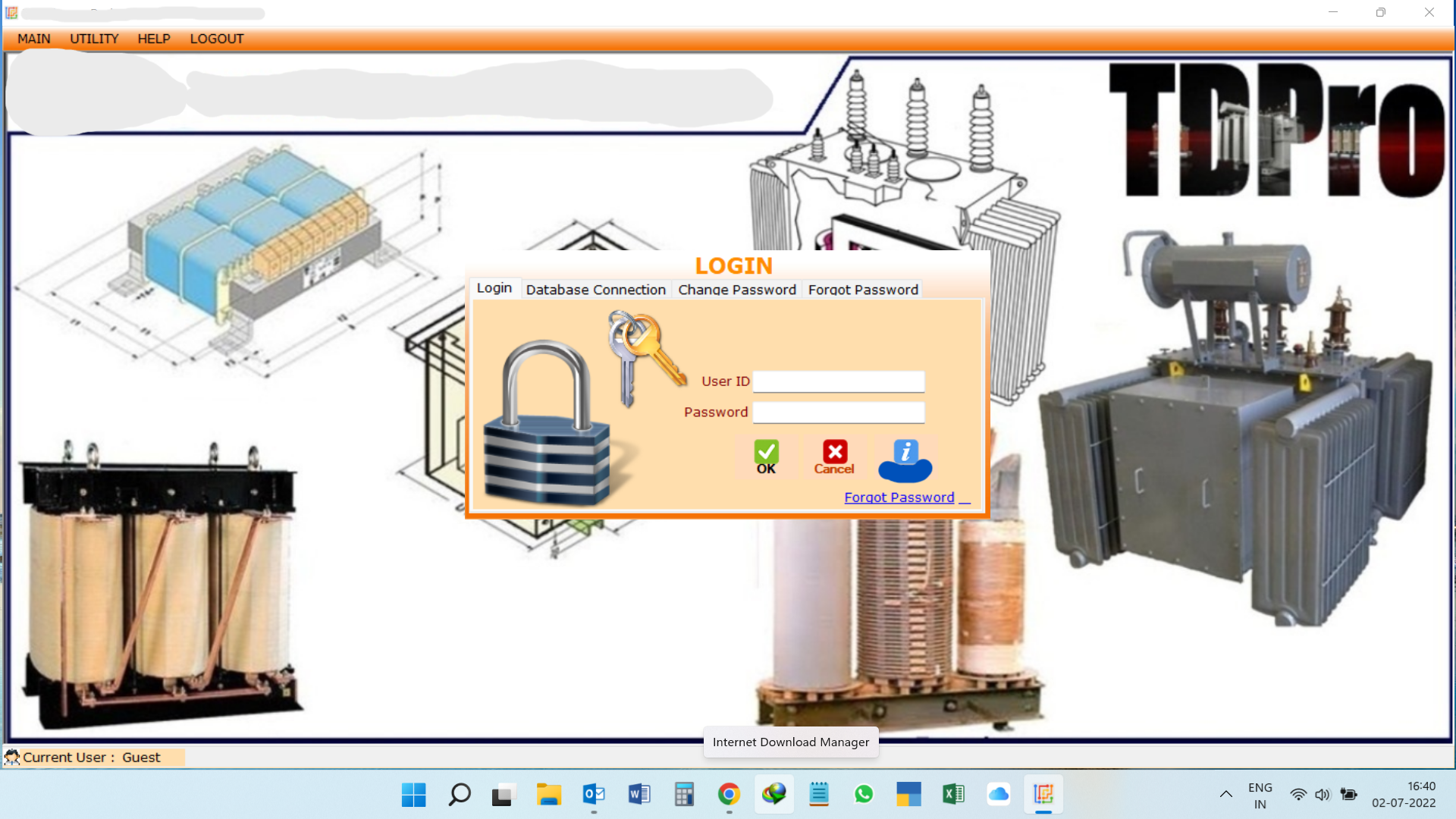

PLANT

We currently operate through the manufacturing unit spread over a total area of 15000 square feet with covered area of over 12000 square feet, located at Gagol Road Industrial Area, Partapur, Meerut. Plant is an independent entity having full-fledged individual facilities for design, manufacturing, material handling, testing and servicing of a wide range of transformers up to 10 MVA, 66 KV Class.